ANALYZE

Welcome to the 3rd phase of a DMAIC Project.

The ANALYZE phase is the beginning of the statistical analysis of the

problem. The practical problem was created earlier. This phase

statistically reviews the families of variation to determine which are

significant contributors to the output.

The statistical analysis

is done beginning with a theory, null hypothesis. The analysis

will "fail to reject" or "reject" the theory.

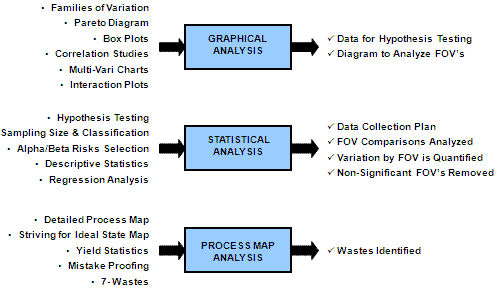

The families of variation and their contributions are quantified and relationships between variables are shown graphically and numerically to provide the direction for improvements.

For example:

You may analyze part-part variation, shift-shift variation, operator-operator variation, machine-machine variation.

By now the MSA has been accepted and the Study Variation has been quantified. The remaining variation is Process Variation.

Recall that:

TOTAL VARIATION = PROCESS VARIATION + MEASUREMENT SYSTEM VARIATION

Most of the analysis at this phase is not whether the AFTER process performance is different than the BEFORE process performance because none of the improvements have been implemented yet, these improvements are now becoming evident and prioritized.

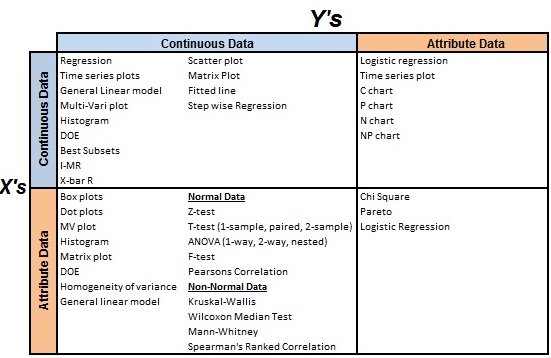

This phase is about statistically comparing means and variation on all families of variation to drill down and quantitatively explain the critical sources of the dispersion.

By the end of the ANALYZE phase the KPIV's that are creating the most significant effect on "Y" should be identified. Any wastes found by employing Lean tools should be identified and prioritized to improve.

The outputs of ANALYZE lead into the inputs to the IMPROVE phase.

The following links cover topics that are often applied within the ANALYZE phase:

Hypothesis Testing:

Nonparametric Tests & Flowchart

Analyzing the sources of Process Variation:

Statistics:

Alpha and Beta Risks (Type I Error and Type II Error)

Pearson's Correlation Coefficient

Spearman's Rho Correlation Coefficient

Distributions:

Shape of the Distribution:

Lean Manufacturing topics:

Takt Time

Project Management Tools

At this point in the project, and perhaps earlier in the MEASURE phase, there were delays or encounters of adversity. Here are a couple tools as reminders to keep the project on track and charging forward.

Statistical Evaluation Tools

Return to the beginning of a DMAIC project

Subscribe for a password to access entire site

Return to the Six-Sigma-Material Home page

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more

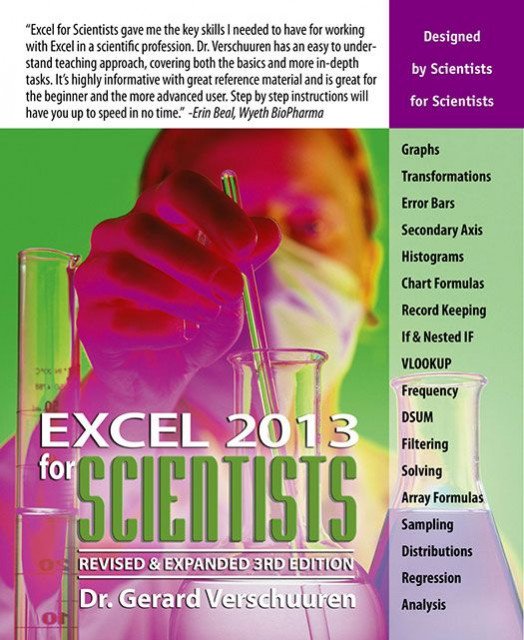

Statistics in Excel

Need a Gantt Chart?