Workcells and Cellular Flow

Designing effective workcells

Other commonly applied terms are:

Prerequisite tools to review when creating a workcell:

Types of Cellular Layouts

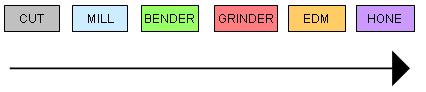

Straight (Linear) Layout

PROS:

CONS:

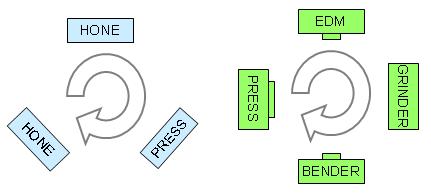

These are possible when there is physical access to both sides of the cell. Sometimes the cell may need to be designed against a wall and a U-shaped cell is the better option since raw and finished parts are on the same side.

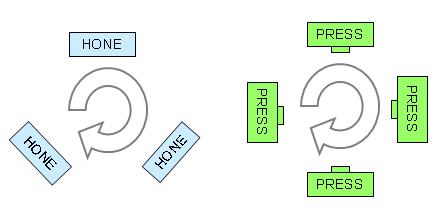

Cage (ONE person & ONE type of operation)

PROS:

CONS:

Cage (ONE person & >1 type of operation)

PROS:

CONS:

U-Shaped Layout

PROS:

CONS:

Assembling a Workcell

Three elements to be considered, the flow of:

- People

- Equipment

- Materials

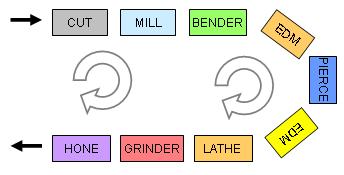

Workcells may be as simple as one of the above, or it may be a combination of them. Multiple U-turn workcells are combinations of straight and U-shaped cells.

GOAL: Workcells are intended to reduce floor space, improve throughput of smaller batches, provide more predictable production, and improve cross-training.

Questions to consider for cellular flow:

Human Factors

Clockwise or Counter-Clockwise?

When designing a U-shaped workcell there should be consideration (if using humans) to whether the operators are left or right-handed and perhaps try to accommodate both.

At some point a direction must be selected and usually counterclockwise is most efficient for people to work within.

Most people are right-handed, right eye is more accurate and stronger for most people. Also consider that track events are usually ran in a counterclockwise direction.

Movement

Strive to:

- Avoid sharp turns, jerks, or rapid acceleration

- Avoid static positions for extended period of time

- Make out of control conditions quickly visual - at eye level

- Keep activity at shoulder height

- Place the most frequently used tools closest to operator and point-of-use

- Use gravity or other mechanical advantages

- Avoid vertical movement and strive for horizontal movement

- Design workstations that suit the operator height (possibly flexible height)

- Design a place for everything (and audit to ensure everything stays in its place)

Common Obstacles of Workcells

Cross Training

This is probably the most influential factor in successful cellular implementation. Not only does this satisfy workcells, but this also curbs the dependence on specialized operators, vacations, and absences. The more operators that are cross-trained the more likely the workcell can provide a consistent output.

Creating the best product families

Typical characteristics are the geometry, tooling, and process step commonality. Must understand the components that takes longest to set-up or has the least capacity (bottleneck - determine with takt time and balanced loading).

Lack of consideration to Human Factors

Past Paradigms

Virtually all implementations of significant change or transformation will meet resistance due to past paradigms. The team designing the cell must be enthusiastic, open-minded, and capable. This first cell created will be judged and will set the precedent for the workcell principle and Six Sigma program going forward.

CHALLENGE EVERYTHING!

Rules, regulations, standards, work instructions, past practices, are all fair game. All of these items are prone to change and the circumstances of their origin may also be different.

Success Factors

Lean Six Sigma Templates and Calculators

Active job openings related to Lean & Six Sigma

Return to the Six-Sigma-Material Home Page

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more