Six Sigma Yellow Belt (SSYB) Training

Six Sigma YELLOW BELT Training

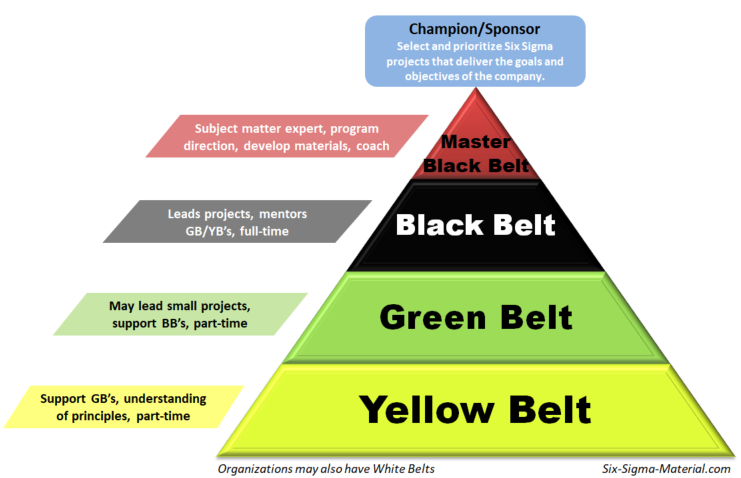

Yellow Belts usually manage projects of smaller scope with shortened expected completion times. They also participate on teams led by a Green Belt or Black Belt and there may be several Yellow Belts and/or Green Belts on a team.

Yellow Belts learn to identify wastes and "see" the hidden factory losses. They are also expected to a have a basic understanding of statistical tools but usually do not get involved in hypothesis testing or DOE's.

Yellow Belts often are not full-time jobs within an organization but rather often used to support GB/BB's with their Six Sigma projects and hold other full-time jobs and expected to use the Six Sigma and Lean principles in their regular full-time job.

Typical Yellow Belt Certification Requirements

Certificate programs are less rigorous than Green Belt or Black Belt programs and usually consist of the following:

- 2-3 days of training with cost typically ranging from $250-$750

- Participation in at least one Six Sigma project

- Evidence using project management tools

- Evidence showing basic application of statistics

- Evidence of understanding the Lean principles

- Written examination

This site has over 180 example certification problems available for subscribers. Many of the problems have further explanations along with additional developmental material that can be found within this site.

If you understand the concepts and answers to these sample problems, you're well on your way to passing a SSYB certification exam.

A SSYB looking to grow into a SSGB or SSBB can help themselves but learning how to analyze data and mastering Six Sigma software programs. You will be surprised how much you learn by handling data and working through the challenges of getting the results and interpreting the results.

Six Sigma Yellow Belt Certification

Yellow Belt Training and Certification usually requires knowledge of the following tools:

- SIPOC

- Process Mapping

- Measures of Central Tendency

- Measures of Dispersion

- Normal Distribution

- 7 wastes

- 5 Why

- Subjective Root Cause Analysis

- Fishbone Diagram

- C & E Matrix

- FMEA

- Mistake Proofing

- Basic Statistics

- Data Collection,

- Data Types

- OEE

- Sampling Methods

- Normality Assumption

- Creating Graphical Tools (Pareto , Box Blots , Scatter Diagrams , Histograms )

Templates, Tables, and Calculators

Return to the Six-Sigma-Material Home Page

Recent Articles

-

Process Capability Indices

Oct 18, 21 09:32 AM

Determing the process capability indices, Pp, Ppk, Cp, Cpk, Cpm -

Six Sigma Calculator, Statistics Tables, and Six Sigma Templates

Sep 14, 21 09:19 AM

Six Sigma Calculators, Statistics Tables, and Six Sigma Templates to make your job easier as a Six Sigma Project Manager -

Six Sigma Templates, Statistics Tables, and Six Sigma Calculators

Aug 16, 21 01:25 PM

Six Sigma Templates, Tables, and Calculators. MTBF, MTTR, A3, EOQ, 5S, 5 WHY, DPMO, FMEA, SIPOC, RTY, DMAIC Contract, OEE, Value Stream Map, Pugh Matrix

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more