DMAIC

Define - Measure - Analyze - Improve - Control

These five steps in a DMAIC project represent a structured roadmap used to improve existing processes. DMAIC projects strive to reduce variation and improve performance about a target.

Each project should follow this general roadmap to completion. Within each of the five phases is more detail about the tools and the outputs that each will provide. A project begins with defining the problem.

CLICK ON A PHASE BELOW

Each phase should undergo a gate review before proceeding to the next. A gate review validates the applicable outputs are complete and prepared for the next phase.

These reviews are done with the coach, sponsor, Green Belt, or Black Belt, Master Black Belt, and possibly a steering committee or upper management.

Don't panic because you can't use all the tools or you don't think there's enough time to use all of them. Each project uses different tools and none will use all of them.

All the tools are there to use if needed (like a toolbox); don't spend valuable time forcing the use of a tool when it isn't applicable. Each project is unique and the tools used will vary from project to project.

There is not a specified amount of time that each phase needs to be completed. Each project will vary on the amount of time spent within each phase.

A critical component of a GB's/BB's success is:

- choosing the correct tools

- in the correct order

- and making the correct interpretations

Some tools are used in more than one phase and on more than one occasion. For example, Pareto diagrams can be applied in every phase and multiple times in a phase.

The tools listed are not listed in exact chronological order or in order of importance as both may vary between projects.

Practice DMAIC Certification problems

There are >180 sample certification problems from each section to help you practice the key focal points of the DMAIC cycle. Click here.

DMAIC Roadmaps

Within each phase are visual aids of the roadmap showing the typical inputs and outputs. Clicking on the phases above will lead further into tutorials and materials on each topic.

These are simplified lessons that are adequate for most projects. Not all topics for a Six Sigma/Lean program are shown as they are virtually infinite and evolving.

A short presentation of the DMAIC roadmaps is available here.

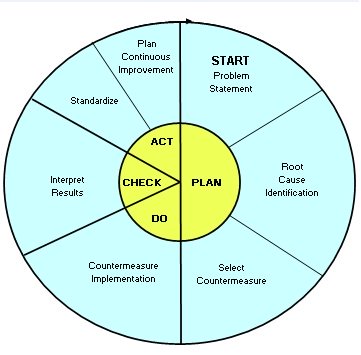

Plan-Do-Check-Act (PDCA)

The DMAIC cycle is similar to the PDCA cycle. Dr. Deming put this tools into widespread use but is commonly referred to as the Shewhart cycle. Sometimes it is referred to as the PDSA ("Study" rather than "Check") to put more emphasis on analysis which is analogous to the DMAIC - ANALYZE phase.

The one more point that can't be emphasized enough is the need to put robust controls in place that SUSTAIN (CONTROL phase) the gains after the ACT part of the PDCA cycle.

The PDCA cycle is found within the A3 problem solving tool that has grown in popularity due to its single sheet of paper (size A3) format using simple tools to solve problems.

Comparing ISO 9000 and Six Sigma

ISO 9000 and Six Sigma have similarities and differences. Click here to read a detailed explanation on each program. Shown below are a couple basic visual aids. This article does a good job explaining the basis for each program.

Difference between ISO 9000 and Six Sigma

ISO - Six Sigma Standards

The ISO (the International Organization for Standardization) has published a few standards due to its global popularity and attempt to standardize the process and reporting. However, the standard does not cover the DFSS process, only DMAIC.

You can preview more and purchase the standard by clicking here.

ISO 13053-1

Quantitative methods in process improvement - Six Sigma Part 1: DMAIC methodology

ISO 13053-1:2011 describes a methodology for the business improvement methodology known as Six Sigma. The methodology typically comprises five phases: Define, Measure, Analyze, Improve and Control (DMAIC).

ISO 13053-1:2011 recommends the preferred or best practice for each of the phases of the DMAIC methodology used during the execution of a Six Sigma project. It also recommends how Six Sigma projects should be managed and describes the roles, expertise and training of the personnel involved in such projects. It is applicable to organizations using manufacturing processes as well as service and transactional processes.

ISO 13053-2

Quantitative methods in process improvement - Six Sigma Part 1: Tools and Techniques

Describes the tools and techniques, illustrated by factsheets, to be used at each phase of the DMAIC approach.

The methodology set out in ISO 13053-1 is generic and remains independent of any individual industrial or economic sector. This makes the tools and techniques described in ISO 13053-2:2011 applicable to any sector of activity and any size business seeking to gain a competitive advantage.

ISO 18404: 2015

Quantitative methods in process improvement - Six Sigma — Competencies for key personnel and their organizations in relation to Six Sigma and Lean implementation.

There is quite a bit of debate over the qualifications for each level of Six Sigma's "belts" and the boundaries that distinguish each of them. This standard defines competencies for attaining of specific levels of competency with regards to Six Sigma, Lean, and "Lean & Six Sigma" in individuals, e.g. Black Belt, Green Belt and Lean practitioners and their organizations. Yellow Belt is not included and excludes the DFSS process.

Browse Six Sigma related job openings

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more