TQM - Total Quality Management

The origins of TQM are subject to debate but most research shows that Walter Shewhart came up with the management ideology in the 1920's.

TQM is a structured system much like a Six Sigma program. When all of its elements are implemented properly, TQM is like a well-built house. It's solid, strong, and exploits the value of synergy. The sum of the collective efforts of everyone in the organization is greater than the sums that each individual can contribute.

Further advances to TQM came from Armand Feigenbaum and the big four:

- W. Edwards Deming

- Joseph Juran

- Philip B. Crosby

- Kaoru Ishikawa

Deming was a student under the instruction of Walter Shewhart. He refined TQM and applied these approaches in Japan in the mid 1950's. As Japan's quality and performance levels surpassed previously dominated fields of work controlled by the U.S., the U.S. companies took notice and adopted the TQM philosophy.

While many failed to properly implement, some did succeed and awards such as the Deming Prize, Shingo Prize, and Malcolm Baldridge Award recognize these companies.

Total - Encompasses the entire organization, supply chain, finance, human resources, IT, processes, and product development. Everyone is involved, practicing what is preached, and regular communication of the purpose driven goal.

Quality - defined by the beholder and can take on many forms and definitions. In the case it is the perception of the customer(s) and the Voice of the Customer. The emphasis is on things being done right the first time.

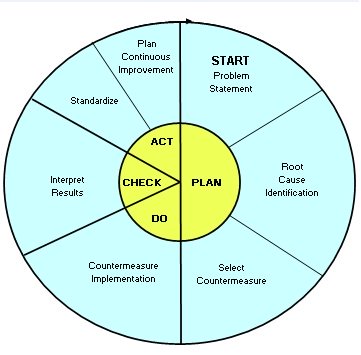

Management - continuous management with cycle such as PDCA cycle, Plan, Do, Check, Act also known as the Shewhart Cycle or Deming Cycle.

Total Quality Management strives to maximize the competitiveness of an organization through the continual improvement of the quality of its products, services, people, processes, and environment.

TQM is not a flavor of the month and if it is implemented in such a way it earns a poor reputation for all the wrong reasons. The same applies for Six Sigma programs. Many companies strive for awards and decorations to bragging rights, public relations, and customer appeal. This may only work in the short term.

Quality requires a never-ending pursuit of improvement. Sustainable and significant breakthroughs often require a lot of time, education, and effort...along with difficult choices.

The methodology includes stakeholders from all levels of the company, especially the leaders of the company. It does not necessarily mean that zero defects or absolute perfection must be achieved as this can be more costly and unpractical than making balanced sustained gains.

TQM requires cross functional cooperation and the elimination of corporate and departmental silos. However, it does not demand radical organizational realignment. It needs the liberation of people from stifling control systems and the tyranny of functionalism which precludes teamwork. Public rewards should be provided (not necessary money) for long term success and remove praise for short term and uncontrolled changes.

Deming's 14 points

Dr. Deming included 14 points in his book "Out of the Crisis" that he believed a company's leaders shall follow to have successful total quality management.

1) Change is constant. Constantly improve the system of operations and service. Management and employees are obligated to continually look for ways to reduce waste and improve quality.

2) Create constancy of purpose for improvement of product and service. Management must change from a short-term focus to delivering long term and creating stability. This requires dedication to innovation in all areas to best meet the needs of the customer.

3) Cease dependence on mass inspection. Create mistake proof processes and focus on proactive rather than being reactive. Inspection is the equivalent to planning for defects; it comes too late, and it is ineffective and costly.

4) End the practice of awarding contracts on the basis of price tag. This is often a contradiction to the typical paradigm on modern supply chain management. Frequently, this leads to supplies or services of low quality. Instead, they should seek the best quality and work to achieve it with a single supplier for any one item in a long-term relationship.

5) Adopt the new philosophy in which mistakes and negativism is unacceptable. Confront poor performance and take the courage to deal with distracting conflict.

6) Institute modern methods of training on the job. Too often, employees learn their jobs from other employees who were never trained properly. They may be prone to follow non-standard instructions and learn bad habits.

7) Institute modern methods of leadership. Lower-level managers must be empowered to inform upper management about conditions that need correction; once informed, management must take action. Barriers (such as reserved parking places for top management) that prevent employees from doing their jobs with pride must be removed.

8) Drive out fear. Employees need to feel secure if they make a mistake or offer suggestions on sensitive topics or positions. They cannot be afraid to ask questions to understand or promote change. People will continue to do things the wrong way or to not do them at all, the top performers will eventually leave. It is necessary for better quality and productivity that people feel secure and have pride to workmanship.

9) Break down barriers between staff areas. Ensure that department or area goals do not suboptimize another's goals or an important customer satisfier. Each discipline must work together as a team for the company as a collective group to achieve the ideal balanced scorecard.

10) Eliminate slogans, exhortations, numerical goals and targets for the work force. Let people put up their own slogans. Although workers should not be given numerical goals, the organization itself must have a goal: continuous improvement.

11) Eliminate work standards and quotas. Quotas focus on quantity not quality. They are usually a guarantee of inefficiency and high cost. To hold a job, a person meets quotas at any cost, without regard to damage to the organization.

12) Allow innovation and experimentation, some will succeed and more will not but the barriers to pride of workmanship should be eliminated. People want to do a good job and are demoralized when they cannot or not allowed. Too often, lack of proper training, misguided managers, unrealistic goals, faulty equipment, and defective material stand in the way.

13) Institute a vigorous program of education and training. Promote cross training and advanced training in specific work fields. Because quality and productivity improvements change the number of people needed in some areas and the jobs required, people must be continually trained and retrained. All training must include basic statistical techniques.

14) Create a structure in upper management that will continually reinforce and lead be example on the 13 points shown above. everybody in the company should strivbe to accomplish and embrace the transformation.

Guiding Principles to TQM

- Successful TQM requires both behavioral and cultural changes.

- Successful TQM aligns itself with organizational management systems and human resource management systems.

- Successful TQM becomes a system within itself by choice.

- Successful TQM system brings two other management systems together with a behavioral and cultural commitment to customer quality.

TQM is infinitely adaptable so each implementation is unique and needs to suit the company. There can be downfalls that are mitigated by first understanding them.

TQM focuses people's attention on internal processes rather than on external results. An asset of TQM is that it gets managers to attend to internal processes. It avoids being number bound and too data driven, or the complete reliance on performance evaluation and measurement, and losing touch with the voice of the customer and the shifting preferences of new, lost, and potential customers.

TQM focuses on minimum standards. Expectations of zero defects and no rework demands distract people from adding value and the price for perfection may not be possible or practical.

TQM does not demand entirely new relationships with outside partners. Working with suppliers is essential as marketing converts to relationship based strategies and partnering with expertise.

Deming's 7 Deadly Diseases

Deming suggested that U.S. companies generally were affected with seven deadly diseases and their rivals have a competitive advantage until they are understood and eliminated.

- Failure to provide adequate time, human and financial resources to support the purpose of quality improvement.

- Excessive health-care costs. A fixed cost that many continue to struggle with providing at affordable rate.

- Excessive legal costs. These are unpredictable but significant cost that places burden on shareholder success.

- Emphasis on short-term profits and shareholder value. Compensation and bonuses (if any) should be based on short and long term performance (>1 year).

- Annual performance evaluations based on observations or judgments. Evaluations should be frequent, real-time, and based on correct facts and data that provide equitable justice.

- The lack of management continuity either from turnover or change in direction. It is difficult for the loyalists of a company to trust the leadership when steering in new directions and never seeming to finish and stabilize before beginning another.

- Management's use of easily available data without regards to what is needed to improve the process. Use of data but lack of understanding the root causes. Examples: Pareto charts of defects but not what causes the defects.

Juran's 10 Steps to Quality Improvement

- Build awareness of opportunities to improve upon

- Establish goals (specific, measurable, attainable, relevant, timely - SMART)

- Organize to achieve goals

- Provide training

- Execute projects to solve problems

- Report progress, maintain accountability

- Give recognition

- Communicate results

- Keep score

- Maintain momentum by instituting a continuous improvement process

Quality Guru's

There are several other gurus that have made significant contributions to the fields of Quality and Six Sigma. You will likely see a question or two on a Six Sigma Certification Exam about them. Click here to learn more about the Quality Guru's.

Test your Six Sigma knowledge with this Six Sigma Practice Exam.

Link to the newest Six Sigma Material

Templates, Tables, and Calculators

Subscribe to get access to entire site

Return to the Six-Sigma-Material Home Page

Recent Articles

-

Process Capability Indices

Oct 18, 21 09:32 AM

Determing the process capability indices, Pp, Ppk, Cp, Cpk, Cpm -

Six Sigma Calculator, Statistics Tables, and Six Sigma Templates

Sep 14, 21 09:19 AM

Six Sigma Calculators, Statistics Tables, and Six Sigma Templates to make your job easier as a Six Sigma Project Manager -

Six Sigma Templates, Statistics Tables, and Six Sigma Calculators

Aug 16, 21 01:25 PM

Six Sigma Templates, Tables, and Calculators. MTBF, MTTR, A3, EOQ, 5S, 5 WHY, DPMO, FMEA, SIPOC, RTY, DMAIC Contract, OEE, Value Stream Map, Pugh Matrix

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more