Baseline Measurement

Description:

A Baseline Measurement is needed to determine the

exact starting point for each project contract primary (Y) and secondary

metrics (y's). These are usually referred to as the "Before" measurement. The final project measurement is called the "After" measurement.

Objective:

The primary metric of interest

(to improve) is the output, Y. The baseline measurement (or beginning performance) is necessary to determine the progress of the

team. Going through his

process from the most recent data collection and sampling may generate a

value different from that shown originally on the project contract.

At

this point, if the difference is significant, the Champion, Sponsor,

and management may need to revise the contract and the financials.

What is a DEFECT?

A defect is characteristic, opportunity, or feature that is non-conforming. Each unit or piece being appraised may have multiple defects.

To

distinguish the spectrum of defect types among units write clear

instructions, use visual aids, and/or add numerical specifications.

Definitions

of defects should be known and held consistent throughout the project.

If it is found that new instructions and aids are necessary then these

should be shared (such as in a SOP or Work Instruction) with all

operators and employees affected so appraisals are reproducible among

everyone.

A Poisson comparison is used for before and after metrics when counting defects per unit since there may be more than one defect per unit that creates a defective unit.

What is a "DEFECTIVE" (or NON DEFECTIVE)?

A piece or unit that is non-conforming or does not meet the customer specification. A defective part or unit may have one or more defects.

A part can be either one of two outcomes: Defective or Not Defective

When there are two outcomes and equal chance each time, this follows the Binomial Distribution

If

there are 80 critical characteristics on a part, then one part can have

up to 80 defects. Whether the part has 1 or 80 defects, it is

considered one defective part.

Numerical statistics are used as

baseline measurements, examples are shown below and calculations can be

found at Basic Statistics

- Z-Score or Benchmark Z-Score

- PPM (see below)

- DPMO

- Cpk

- Cp

- Ppk

- Pp

- Cpm

- Throughput Yield (First Pass Yield)

- Rolled Throughput Yield (RTY)

- Final Yield (FY)

- Normalized Yield (NY)

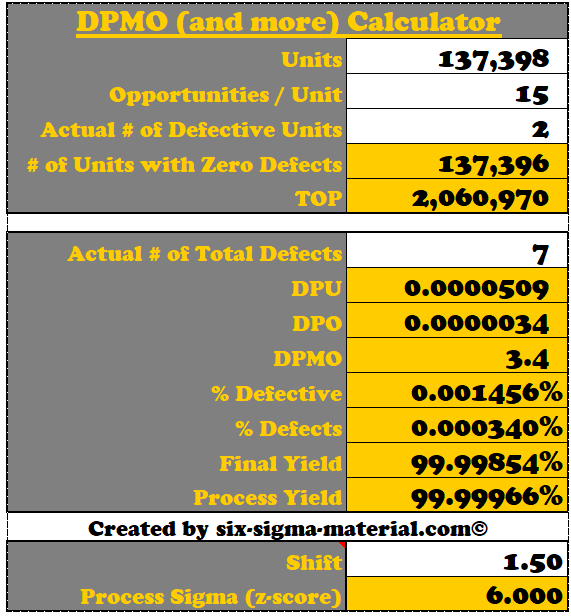

DPMO vs PPM

DPMO is not the same as PPM since it is possible that each unit

(part or item) being appraised may have multiple defects of the same

type or may have multiple types of defects. A part is defective if it

has one or more defects. The number of Defectives can never exceed the number of Defects.

If each part only has one characteristic that can be a defect, then DPMO and PPM will be the same.

DPMO will always exceed or equal PPM for a given yield (sigma level) performance.

See our DPMO and z-score calculator to help you understand these various terms of DPU, TOP, DPMO, Process Sigma, % Defective, etc.

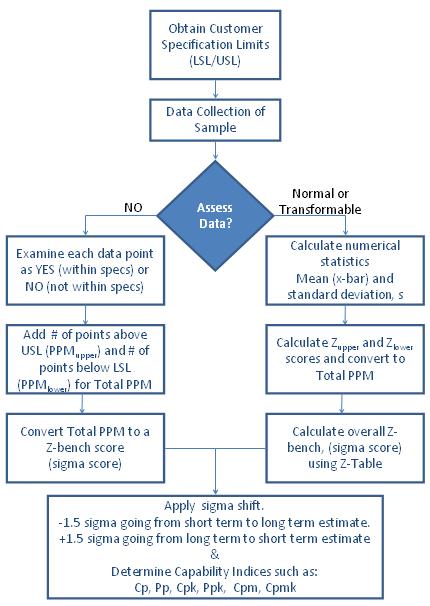

Process Capability Flowchart for Continuous data

Assessing continuous data is preferred over attribute data. When possible convert to variable data as it provides more information. Follow the flowchart shown below to determine process capability when analyzing continuous data.

|

Before and After Capability Roadmap This download is available to members |

Return to Process Capability Indices

Return to the Six-Sigma-Material Home Page

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more