Capability Index, Pp

Pp is a process index that numerically describes the long term capability (Cp is short term indicator) of a process assuming it was analyzed and stays in control.

It is an option (along with z-score and PPM) when describing process baseline measurement in the MEASURE phase or in the CONTROL phase when obtaining the final performance analysis.

As with all the process capability indices, the process must be in control before assessing capability. Use time-series and control charts to determine process control. If the process is out of control (i.e. still rising with upward trend), then assessing current process performance is not likely to reflect the long term performance.

Both Pp and Cp relate the variation of the distribution to the allowable tolerance specifications.

Similar to Cp, this capability index is only a function of the standard deviation, not a nominal (target) value that may be historical or provided by the customer.

It also requires input from the customer for the lower specification limit (LSL) and upper specification limit (USL).

where the estimation for sigma is (also sometimes called the overall, long-term, or cumulative data sigma (and also for Ppk)

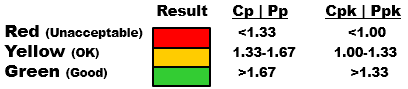

Acceptability

Values >1.00 and >1.33 are common acceptability levels for Pp.

Note:

The Pp index accounts for all the short term sample variances (Cp) and typically will be lower over the long term. The standard -1.5 sigma shift from short term to long term doesn't exactly apply but there is a commonly accepted reduction of acceptability from Cp to Pp.

Click the link to examine the difference between short term and long term samples.

DETERMINING ACCEPTABILITY LEVEL

Customers vary in their minimum requirement for the values of capability indices. As the pursuit for perfection increases these minimum acceptability levels will increase. In this case it means that process must perform with less and less variation.

The acceptability level may be available in the form of published standards or it may need to be requested specifically. The amount of samples required for capability analysis and control charts can also vary by customer and needs to be determined before starting these items.

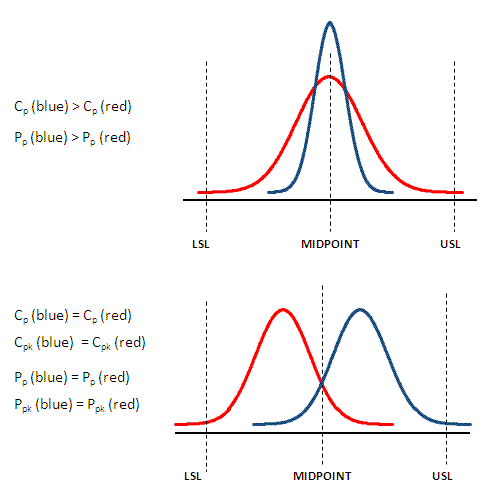

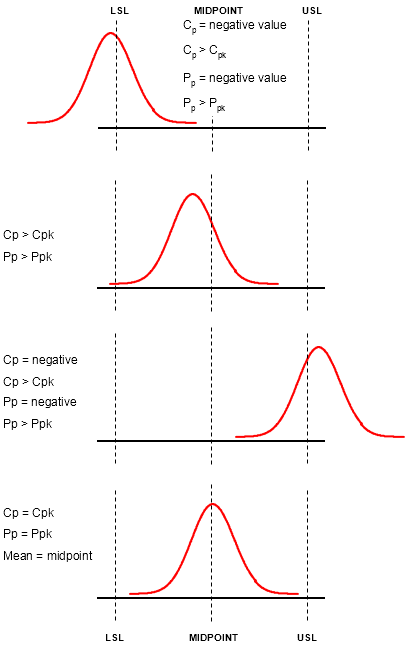

Visual Relationship of Capability Indices

Additional Visual Aids

General rule of thumb

Other Capability Indices

Site Membership

Click for a Password

to access entire site

Six Sigma

Templates & Calculators

Six Sigma Modules

The following are available

Click Here

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Process Mapping

Capability Studies

MSA

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

T Tests

1-Way ANOVA

Chi-Square

Correlation and Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Effective Meetings

OEE

Takt Time

Line Balancing

Practice Exam

... and more