A3 Problem Solving Tool

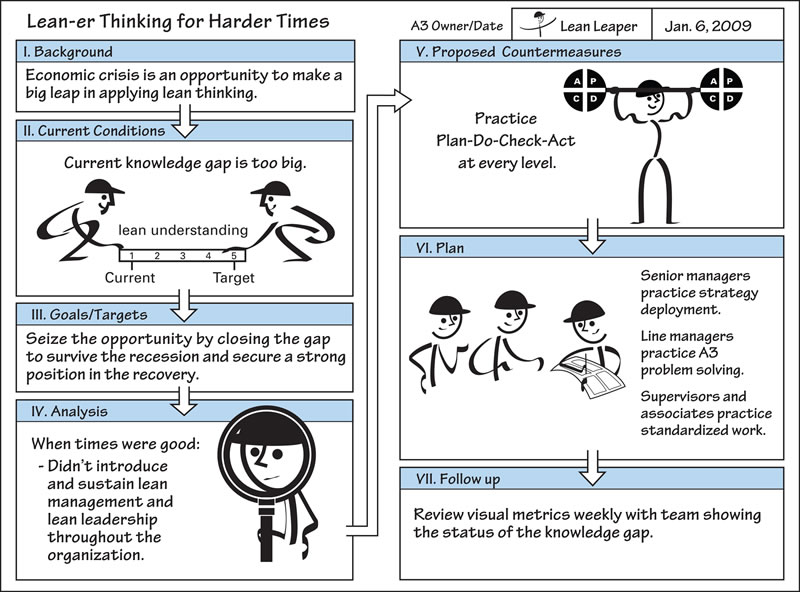

The A3 methodology is problem solving tool first introduced by Toyota and is more than a root cause indicator such as a Fishbone Diagram. Toyota's goal was to capture the problem, the analysis, corrective actions and tracking of action plans all onto one sheet of paper.

The A3 name comes from the size of the paper. It's an international term for paper measuring 297 mm wide by 420 mm in length. The closest paper size commonly used in the United States is 11"*17".

The A3 problem solving tool was widely used at Toyota to standardize and simply communication. The intent is to be simple, foster communication, and visualize the subjective analysis of root causes.

The project manager then adds facts and figures to confirm subjective input and encourage more dialogue to ensure the most valuable improvements are implemented.

The A3 format is designed to have all the following on this one sheet of paper:

- Problem identification

- Clarification

- Analysis

- Resolution

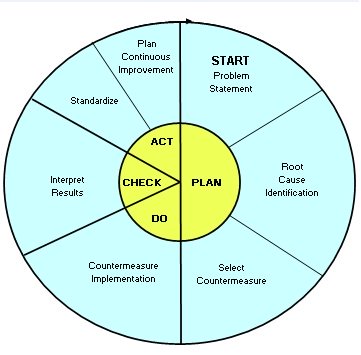

A3 is a key component of Toyota problem solving process based on the PDCA cycle. It applies to all levels of the workforce. The Plan-Do-Check-Act cycle is fully encompassed in this tool from the scope to sustaining the gains and spreading them company wide.

It is a communication tool for workers to report problems and gain support to address issues and fix them. For that reason, the A3 is often created by hand and posted in highly visible area.

The A3 progress is typically reviewed (during audits or GEMBA walks) on a daily basis. It takes time to complete the tool, it isn't intended to be done in one sitting.

Like many of the Six Sigma and Lean tools, they won't be successful unless supported by the culture of continuous improvement and passion to embrace change, experiment, and have the genuine support from all levels within an organization.

A3 Structure

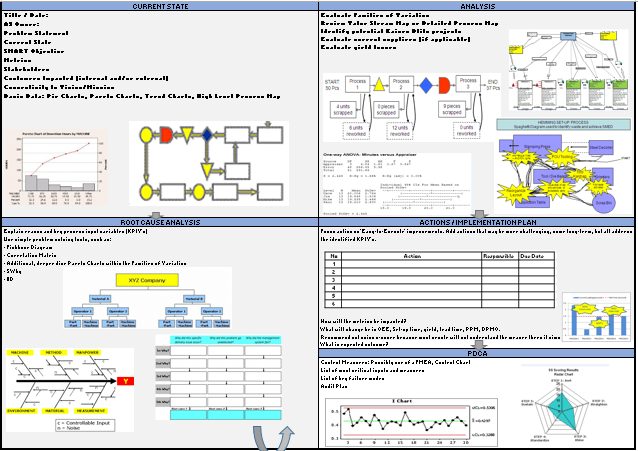

There are several variations of the flow within the sheet. Exactly how each sheet of paper may look, the tools used, depends on the problem. The general flow is show below however the most important thing is to capture the key relevant information, in sequential flow, on the paper...the exact location on the paper isn't as important.

Left Side of A3 - PLAN

Top Left Corner: Similar to a Project Charter. A background and statement of the current state along with a problem statement. A statement about the objective and desired final state.

Bottom Left Corner: Support data such as Pareto Diagrams, Box Plots, Spaghetti Diagrams, Process Map, Time-Series Plot. The subjective root cause analysis usually involving a Fishbone Diagram and possible simple C&E Matrix and FMEA. Also possible use of the 5-Why methodology.

Right Side of A3 - DO / CHECK / ACT

Upper Right Corner: Action register with accountability and dates. Answer the who, what, when, where, and how.

Lower Right Corner: A measurement plan to verify the results and check them to ensure goals are met. Also a plan to sustain the gains and implement gains to other areas of the company.

A3 at Six-Sigma-Material.com

A3 at Six-Sigma-Material.comA3 Template

|

Download this free .zip file for an A3 template in Excel. |

More Templates, Tables, and Calculators

Return to the Six-Sigma-Material.com home page

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more