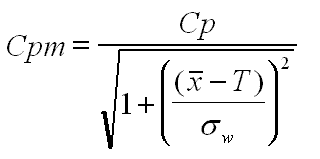

Cpm

Cpm is a capability index, also known as the Taguchi capability index, that is a function of the specification limits, mean of the process, and a provided target, T.

The indices of Cpk and Ppk focus on centering of the mean of the distribution around the midpoint of the tolerances (USL+LSL/2) but this is not always the customer target.

Sometimes the customer may specify targeting the upper or lower end of the tolerance. This could be due to past experiences, part weight reduction, and many other reasons.

The value of Cpm is always > 0 and assumes normally distributed process output and uses the sample standard deviation calculation for sigma (within).

AND

The links below explain other process capability indices.

Return to the MEASURE Phase

Return to the CONTROL Phase

Return to Basic Statistics

Return to Six-Sigma-Material Home Page

Site Membership

Click for a Password

to access entire site

Six Sigma

Templates & Calculators

Six Sigma Modules

The following are available

Click Here

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Process Mapping

Capability Studies

MSA

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

T Tests

1-Way ANOVA

Chi-Square

Correlation and Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Effective Meetings

OEE

Takt Time

Line Balancing

Practice Exam

... and more