IATF 16949: 2016

This international automotive standard IATF 16949 (also seen as ISO/TS 16949) incorporates an emphasis on Total Productive Maintenance (TPM), its metrics, and overall proactive management of equipment and supporting processes.

This is one of the most widely applied international quality management standards and is probably the most widely used. It helps to standardize the complex supply chain that stretch across international borders to hold all suppliers to a level playing field.

This is another evolution of technical specifications that has its roots within TQM and based on ISO 9001. The document is a guide for a quality management system which provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the automotive industry supply chain and assembly process.

Companies strive to get certified to be able to participate as suppliers to with automotive supply chain. Many suppliers, especially Tier One, require some level of certification and most basic is often IS0 9001 but more often it is becoming ISO/TS 16949.

A certification last for three years with audit being conducted by the International Automotive Task Force (IATF).

This website covers the section related to continuous improvement:

- Section 8.5.1.5: Total Productive Maintenance

|

|

|

IATF 16949: Section 8.5.1.5

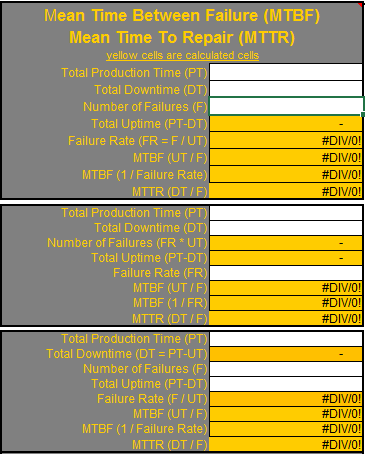

Within TPM there are three primary metrics that could be applied, but more could be used.

Click on each to learn more and work through example calculations. OEE and MTTR are more reactive metrics, while MTBF is used to predict the next failure and apply preventive actions before that next failure, a proactive metric.

It's one thing to know when a failure will occur, then maintenance can be planned and take place just prior to the failure. But it's also important to extend the MTBF as long as possible.

Predictive maintenance tools, such as oil analysis and thermal imaging, can be performed regularly to avoid unnecessary maintenance and monitor how changes in maintenance are affecting the equipment.

The goal of Predictive Maintenance is to have consistent equipment performance and reliability and predictability.... in other words, to reduce the variation in its output. Machines should be doing what they are supposed to do, when you want to do it.

The metrics are used as inputs into the Management Review, Section 9.3

OEE Module

MTBF and MTTR Calculator

Subscribe to access entire site (members get a MTBF and MTTR calculator)

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more