Explaining the constant, d2

In an MSA, d2 is a constant used when calculating an estimate of the process standard deviation from the average range (R-bar) of subgroups. It represents the expected value of the sample range when the underlying distribution is normal with a standard deviation of 1.

The primary use of the d2 constant is to convert the average range (R-bar) of measurements taken within a subgroup into an estimate of the process standard deviation (sigma, σ). This is particularly helpful in process capability analysis and control chart construction when the subgroup size (n) is known.

The formula for estimating sigma (standard deviation) is: σ = R-bar / d2 (aka Study Variation in this case). This standard deviation is often referred to as a measure of "within subgroup variation".

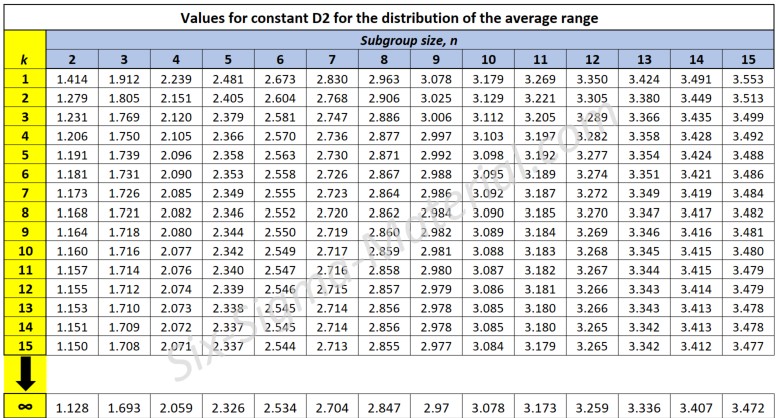

The value of d2 depends on the subgroup size (n) and can be found in tables such as shown below. Most statistical software will have these constants as well.

d2 is often used in conjunction with other control chart constants like d3 and d4. d3 is used to calculate the UCL for range charts and d4 is used to calculate the UCL for X-bar charts.

Recent Articles

-

Process Capability Indices

Oct 18, 21 09:32 AM

Determing the process capability indices, Pp, Ppk, Cp, Cpk, Cpm -

Six Sigma Calculator, Statistics Tables, and Six Sigma Templates

Sep 14, 21 09:19 AM

Six Sigma Calculators, Statistics Tables, and Six Sigma Templates to make your job easier as a Six Sigma Project Manager -

Six Sigma Templates, Statistics Tables, and Six Sigma Calculators

Aug 16, 21 01:25 PM

Six Sigma Templates, Tables, and Calculators. MTBF, MTTR, A3, EOQ, 5S, 5 WHY, DPMO, FMEA, SIPOC, RTY, DMAIC Contract, OEE, Value Stream Map, Pugh Matrix

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more