NP-Chart

Attribute (Discrete) Control Charts

NP-Chart is an attribute control chart used when plotting:

- DEFECTIVES

- BINOMIAL ASSUMPTIONS SATISFIED

- CONSTANT (fixed) SAMPLE SIZE (subgroup size)

Each observation is independent.

Use this chart to develop upper and lower control limits (UCL and LCL) and determine performance of process over time. This chart plots the number of non-conforming units or pieces. Each piece or unit may have one or more defects that make it defective.

The fixed subgroup size allows for constant control limit values, the is not a need to recalculate the control limits for each sample size. If the defective level is very low, (sample size * average % defective < 5), then apply binomial distribution exact limits.

The NP Chart is used to detect shifts >1.5 standard deviations. In order to detect smaller shifts there are other charts that can be applied to variable and attribute data such as Exponentially Weighted Moving Average (EWMA) and Cumulative Sum of Quality Characteristic Measurement (CUSUM).

Below is sample set of data and the NP-Chart follows.

The chart indicates that the process is in control. The control tests that were used all passed in this case. Recall, there are a variety of control tests and most statistical software programs allow you to select and modify these criteria.

The Voice of the Process" has a centerline which indicates that on average there will be 9.96 defective units (not the number of defects) on a given run and expect between 1.69 (2) and 18.23 (18) defective units per run.

Reminders for using NP-Charts:

- It is not possible to have more defective units than units produced.

- P-bar is the average percent of defective units per group/lot/sample size

- Constant lot (group) size.

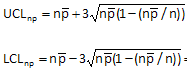

Calculating the 3 sigma Control Limits

Six Sigma Certification Problem

With 50 samples (n=50), a process has a p-bar of 0.25. What are the upper and lower three sigma limits (UCL/LCL)?

A) 0.25 and -0.25

B) 12.5 and -12.5

C) 21.69 and 3.31

D) 15.56 and 9.44

Answer: C

Find n*p-bar (the centerline) first which is 50 * 0.25 = 12.5

There are over additional 180 sample DMAIC certification problems that can be accessed here

Site Membership

Click for a Password

to access entire site

Six Sigma

Templates & Calculators

Six Sigma Modules

The following are available

Click Here

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Process Mapping

Capability Studies

MSA

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

T Tests

1-Way ANOVA

Chi-Square

Correlation and Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Effective Meetings

OEE

Takt Time

Line Balancing

Practice Exam

... and more