Just-in-Time Manufacturing

Quality guru Shigeo Shingo is credited with developing the concept of Just-in-Time Manufacturing (JIT) which involves the coordination of:

- Suppliers

- Workers

- Materials

- Information

All stakeholders in the project work to ensure just the right material, in the right amounts, arrives at the right time. Everything must flow as planned.

JIT is a system the provides products and services in the correct quantities at the correct time.

Applying JIT adds a new risk to most companies compared to their traditional operating methodology. A minor error or interruption in the flow of materials or information can be very costly and outweigh the intended benefits. JIT should not be forced or implemented with significant investment if forethought and enterprise-wide engagement.

Companies apply JIT to receive goods only as they are needed in the production process which normally has the effect of reducing inventory costs. A reduction in inventory enhances cash flow but doesn't always flow to the bottom line.

That is the first step. Then the willingness to properly plan within their own four walls and the entire supply chain.

A small error in planning a JIT program can lead to significant downtime in a workcell or assembly line resulting in a sizable (and unplanned) impact to cash flow and bottom line.

To achieve the best results and take the maximum risk in reducing inventory levels, JIT requires the following prerequisites BEFORE implementation:

- Ability to reasonably forecast demand (ideally only common cause variation but if there is special cause variation it needs to be foreseeable)

- Properly calculated Kanban levels and replenishment signals

- Loading and Takt Time calculations completed

- Defect free material

- Supply Chain engagement - on-time delivery windows established

- Employees and all stakeholder engagement

- Training in the principles of Lean Manufacturing for all stakeholders

- Proper staffing levels and contingency plans for tardiness, absenteeism

- Workcell review (if applicable)

- Predictive Maintenance program - understand MTBF and MTTR

- Visual Management

- Point-of-Use tools and support items for operators (if necessary)

- Properly calculated Economic Order Quantity (EOQ) or Economic Lot Size (ELS)

The goal again is to minimize inventory, prevent over-production, and optimize the use of floor space. Of course, all of this without sacrificing customer satisfaction, quality, and delivery (or the overall Voice of the Customer, VOC).

Just-in-Time Manufacturing emphasizes smaller quantities of supplies and more frequent deliveries. This often equates to tension with suppliers as they need to absorb the burden of freight, labor, and lower economies of scale. Companies and suppliers must work on relationship marketing to get the best solution that strengthens both companies.

Materials must be defect free, information should be visual, real-time, and people should have their work loaded distributed to meet the takt time and balanced, and suppliers shall be sequenced to deliver and pull at the right time.

The effectiveness of JIT is compromised when there is waste or out of control conditions (outliers or special cause). This includes inconsistent material performance, delivery schedules, absenteeism, interruptions, unreliable systems, lack of poka-yokes, improperly established Kanban levels or EOQ's, poorly timed replenishment routes, and more.

Buying materials with long delivery times present another company cost-benefit analysis. Often large purchases allow for significant unit price discounts but at the expense of additional supply chain risk if there is a quality problem.

Other issues could be storage space for bulk orders and depending on the freight terms could lower working capital unless consignment or other delayed payment arrangement is worked out.

Toyota City in Japan resembles a campus with manufacturing and assembly in the hub and most suppliers and employees nestled in a tight radius allowing for JIT and predictable, low cost, output.

This has the advantage of supplier partnering, quick cash conversion cycles, reduced risk of late delivery, low inventory, stable inventory, and economies of scale.

Caution with Automation within JIT

Automation is not always a viable solution. While programmable and consistent when they work, these systems can be costly to implement, maintain, cause excessive downtime, and lack flexibility. Machines, conveyors, forklifts are not as flexible as people.

Often times the Takt Time for a product line can change quickly and having affordable and responsive operators can be a better solution.

People can adapt to variation easier and quicker than robots and machines. People also want to have a more satisfying role in their job, many seek fulfillment and interest in their work and want to feel like their making a contribution.

Learn about Jidoka.

|

|

|

Consideration to Human Factors - proper ergonomics

- Proper lighting

- Spring loaded bins or utilize gravity to help material flow when possible

- Point-of-Use Tools

- Allow work with good posture

- Avoid static positions (keep people moving)

- Make workstations mobile if possible (use casters) also to ease cleaning

- Perform work at proper heights

- Avoid sudden acceleration or deceleration

- Avoid excess forces and noises

- Allow workstations to be adjustable in position if possible

- Allow access to turn safely and clearance for maintenance and tuggers.

- Use power tools

- Communize adjustments (knobs, bolts, screws, etc.)

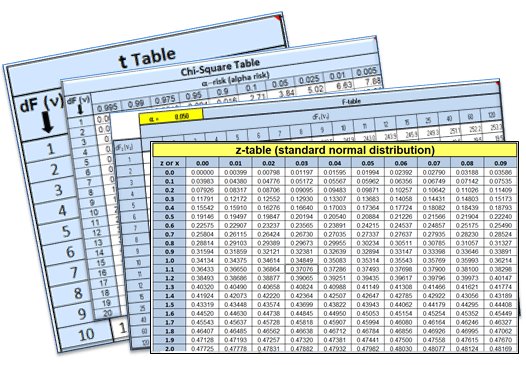

Download Statistics Tables (free to subscribers)

Return to LEAN Manufacturing

Templates, Tables, and Calculators

Six Sigma practice certification problems

Return to the Six-Sigma-Material Home Page

Site Membership

Click for a Password

to access entire site

Six Sigma

Templates & Calculators

Six Sigma Modules

The following are available

Click Here

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Process Mapping

Capability Studies

MSA

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

T Tests

1-Way ANOVA

Chi-Square

Correlation and Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Effective Meetings

OEE

Takt Time

Line Balancing

Practice Exam

... and more